Sino Composite provides Vacuum bagging material series including Vacuum Bagging Film, Release Film, Peelply, Sealant Tape, Pressure Sensitive Tape, Breather, Infusion Mesh, etc.

Vacuum Bagging is a technique that imposes vacuum pressure to the surface of the object between the mouldtooland the vacuum bag to optimize the fiber-to-resin ratio of the product. Therefore, it can improve the mechanical performance of the product.

Usually, the vacuum bagging process canbe classified as two types:

1. Vacuum bagging for resin infusion. Infuse the resin to dry preform of fabrics layers with a stable pressure.

2. Vacuum bagging for prepreg or wet lay-up Impose vacuum pressure onfabricsimpregnated with resin.

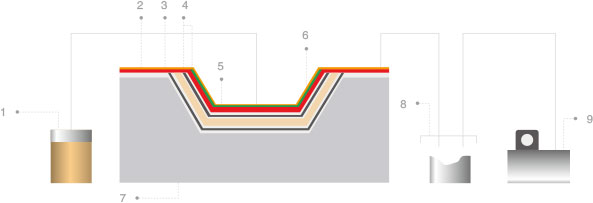

[ Vacuum bagging for resin infusion ]

1.Resin tank

2.Vacuum bagging film

3.Peelply

4.Fiber reinforcements

5.Structural core materials

6.Infusionmesh

7.Tooling

8.Resin reservoir

9.Vacuum pump

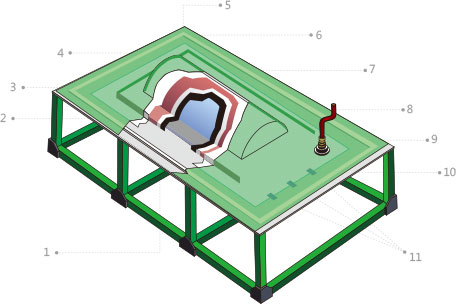

[ Vacuum bagging for prepreg or wet lay-up ]

1.Sealant tape

2.Mould release agent

3.Breather/Bleeder fabric

4.Vacuumbaggingfilm

5.Release film (perforation or none)

6.Peelply

7.Laminate

8.Vacuum hose

9.Quick connector

10.Vacuum valve

11.Pressure sensitive adhesive tape

| Product | Model | Thickness μm |

Max Width m |

Temerature ℃ |

Material | Feature |

| BAGGING FILM | CVF120 | 75 | 16 | 120 | PE/PP | Vacuum infusion |

| CVF170 | 50/65/75 | 8 | 170 | PE/PP/PA co extrued | ||

| CVF200 | 50/75 | 8 | 200 | PA | ||

| CVF220 | 50/75 | 3.05 | 220 | PA-modified | Autoclave | |

| CVF230 | 50/75 | 3.15 | 230 | PA-modified |

| Product | Model | Thickness μm |

Max Width m |

Temerature ℃ |

Material | Feature |

| RELEASE FILM | CVR120 | 25/30 | 1.52 | 120 | PE | Ambient temperature |

| CVR150 | 30/50 | 150 | PP | Intermediate temperature | ||

| CVR230 | 25/30 | 230 | ETFE | Autoclave | ||

| CVR260 | 25/30 | 260 | FEP | |||

| CVR315 | 25/50 | 1.22 | 315 | PETFE |

| Product | Model | Weight g/m² |

Temperature ℃ |

Material | Feature |

| PEELPLY | CVP180 | 60-105 | 180 | PE | Cost-effective |

| CVP200 | 60-105 | 200 | PA6 | ||

| CVP230 | 60-105 | 230 | PA66 | High temperature | |

| CVP260 | 150/210 | 260 | GF+PTFE |

| Product | Model | Weight g/m² |

Width m |

Temperature ℃ |

Material | Feature |

| BREATHER | CVB190 | 150/250/340 | Customizable | 190 | PE | Cost-effective |

| CVB230 | 200/40 | 230 | PA | High-performance |

| Product | Model | Thickness mm |

Temperature ℃ |

Feature |

| SEALANT TAPE | CVS120 | 1-3 | 120 | Ambient temperature |

| CVS150 | 3 | 150 | ||

| CVS180 | 3 | 180 | Prepreg, oven & autoclave | |

| CVS210 | 3 | 210 | ||

| CVS230 | 3 | 230 |

| Product | Model | Thickness mm |

Temperature ℃ |

Feature |

| PRESSURE SENSITIVE TAPE | CVPS200 | 0.06 | 200 | PE, with silicone adhesive |

| CVPS260 | 0.12 | 260 | GF+PTFE, one side with silicone adhesive |

| Product | Model |

Weight g/㎡ |

Width |

Temperature ℃ |

Material | Feature |

| INFUSION MESH | CVM | 80-230 | Customizable | 120 | PE | Extruded |

| CVM | 135/160 | 100 | PE | Woven |

| Product | Temperature ℃ |

Feature | |

| TOOLS | Vacuum Valve | 200-270 | Aluminum/Stainless steel/Carbon steel |

| Quick Connector | 200-287 | Cast iron/Stainless steel/Carbon steel | |

| Reinforced Hose | 260-270 | Metal+silicone sleeve | |

| Vacuum Pump | Low noise High vacuum degree |

||

| Resin Collector | 120 | Cast iron/Stainless steel | |

| T-connector | 120 | PE | |

| Resin Inlet Base | 160 | PP | |

| Spiral Tube | 120 | PE | |

| Resin Tube | 120 | PE | |

| Vap Membrane | 150 | Semi-permeable membrane | |